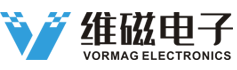

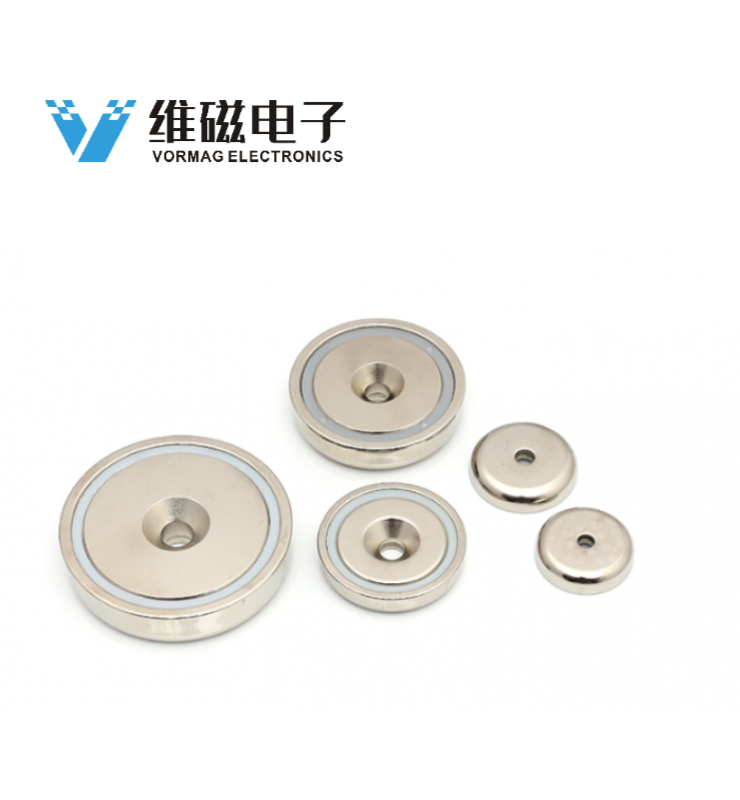

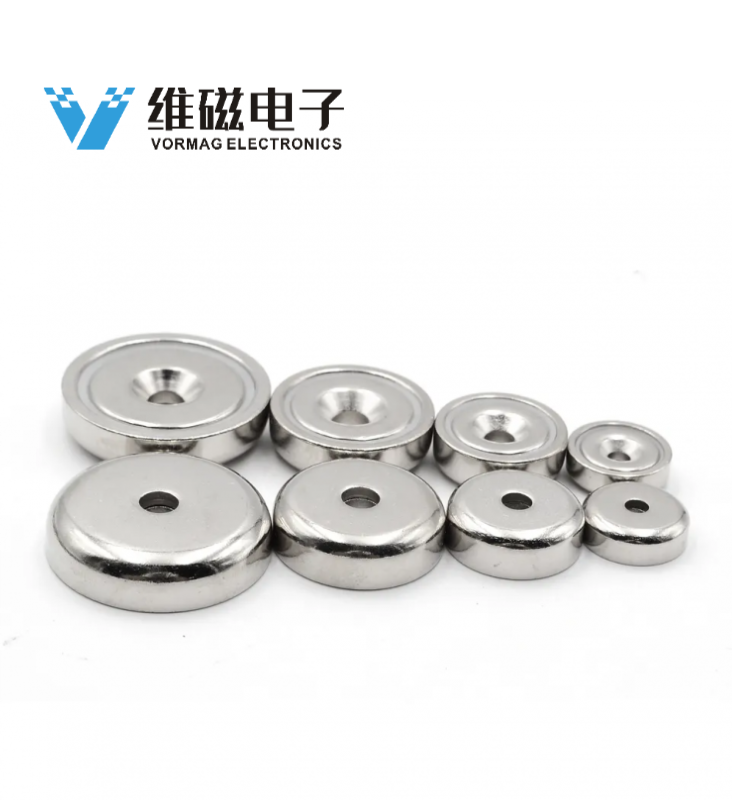

Description: Counter sink cup magnet assemblies are magnetic assemblies consisting of a steel cup and a neodymium magnet base containing a countersunk, or cone-shaped, hole.

This countersunk hole provides a space for a screw to be put through the assembly and have the tapered head of the screw fit flush with the magnet in the assembly, allowing for a variety of mounting options.

If you didn't find the parts will accommodate your application. We will gladly help you to choose the right magnet and advise you personally.

This is a document of products models regarding this pot magnet type.

![]() products models_Neodymium pot magnets with countersunk hole.pdf

products models_Neodymium pot magnets with countersunk hole.pdf

How to measure pull force of a magnet?

The pull force of a magnet is a measure of the strength of the magnet's magnetic field and its ability to attract ferromagnetic materials. There are several methods for measuring the pull force of a magnet, here is an example testing video of Pull Tester, that is a pull tester is a specialized device that is used to measure the pull force of a magnet. It consists of a platform that holds the magnet and a load cell that measures the force required to pull the magnet away from the platform.

Magnetic pull strength is a reliable method of measuring the maximum strength, or holding power, that a magnetic assembly has before it is separated from a steel plate. It is obviously the higher the pull strength, the greater the strength of the magnetic assembly.

The testing process and condition: The entire magnetic surface of our magnetic assemblies is tested against a .5 inch thick, ground steel plate. Beginning with a clean magnetic surface and a clean steel surface, the magnetic assembly is attached to the center of the steel plate. A hook with a measuring device (dynamometer) is attached to the assembly. It slowly pulls the magnet upward until sufficient force (breakaway force) to break the assembly from the plate has been created. The measuring device records the pounds pull. By repeating this test multiple times, we can establish an accurate reading and pounds pull rating (or Max Force) for the magnetic assembly.

As the pull force is measured in laboratory conditions, most real world applications will not reach the maximum pull strength listed. It is important to note that pull strength will vary with:

Differing thicknesses of steel

Types of steel composition

Coatings on the steel, including paint or grease

Uneven surface area, such as rust